What Industries Are the Application Scenarios of Ceramic Resistors Included In?

I. Introduction

Ceramic resistors are a vital component in modern electronic devices, known for their durability and reliability. These resistors are made from ceramic materials, which provide excellent thermal stability and electrical insulation. As technology continues to advance, the demand for high-performance components like ceramic resistors has surged, making them indispensable in various industries. This blog post will explore the characteristics of ceramic resistors and their application scenarios across multiple sectors, including electronics, automotive, aerospace, medical devices, renewable energy, and industrial automation.

II. Characteristics of Ceramic Resistors

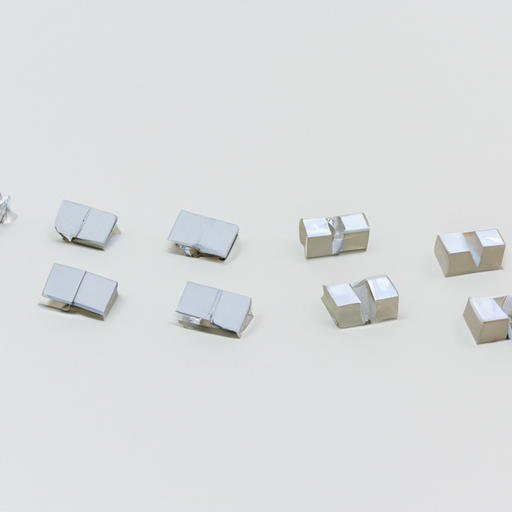

A. Composition and Manufacturing Process

Ceramic resistors are typically composed of a mixture of metal oxides, which are processed and sintered at high temperatures to form a solid ceramic body. This manufacturing process results in a resistor that can withstand extreme conditions, making it suitable for various applications.

B. Key Properties

1. **High Temperature Resistance**: Ceramic resistors can operate at elevated temperatures without degrading, making them ideal for applications in harsh environments.

2. **Stability and Reliability**: These resistors exhibit minimal drift in resistance values over time, ensuring consistent performance in critical applications.

3. **Low Noise Characteristics**: Ceramic resistors produce less electrical noise compared to other resistor types, which is crucial in sensitive electronic circuits.

4. **High Voltage Tolerance**: They can handle high voltage levels, making them suitable for power applications where other resistors might fail.

C. Comparison with Other Types of Resistors

Compared to carbon film or metal film resistors, ceramic resistors offer superior thermal stability and voltage handling capabilities. While other resistors may be more cost-effective for low-power applications, ceramic resistors are preferred in high-performance scenarios where reliability is paramount.

III. Overview of Industries Utilizing Ceramic Resistors

A. Electronics and Electrical Engineering

Ceramic resistors are widely used in the electronics and electrical engineering sectors. They play a crucial role in:

1. **Consumer Electronics**: Devices such as smartphones, tablets, and laptops rely on ceramic resistors for circuit protection and signal conditioning.

2. **Industrial Equipment**: Heavy machinery and industrial automation systems utilize ceramic resistors for power management and control circuits.

3. **Telecommunications**: In communication devices, ceramic resistors help maintain signal integrity and manage power distribution.

B. Automotive Industry

The automotive industry has seen a significant shift towards electric and hybrid vehicles, increasing the demand for ceramic resistors in:

1. **Electric Vehicles**: These vehicles require robust components that can handle high voltages and temperatures, making ceramic resistors ideal for battery management systems.

2. **Engine Control Units (ECUs)**: Ceramic resistors are used in ECUs to ensure precise control of engine functions and emissions.

3. **Safety Systems**: Advanced safety features, such as anti-lock braking systems (ABS) and airbag deployment systems, rely on the reliability of ceramic resistors.

C. Aerospace and Defense

In the aerospace and defense sectors, where reliability is critical, ceramic resistors are employed in:

1. **Avionics**: Navigation and communication systems in aircraft depend on ceramic resistors for stable performance.

2. **Military Applications**: Equipment used in military operations requires components that can withstand extreme conditions, making ceramic resistors a preferred choice.

3. **Space Exploration**: In spacecraft, ceramic resistors are used in various systems, including power management and environmental control.

D. Medical Devices

The medical field relies on ceramic resistors for:

1. **Diagnostic Equipment**: Devices such as MRI machines and ultrasound equipment require precise and reliable components.

2. **Therapeutic Devices**: Equipment used for treatment, such as radiation therapy machines, benefits from the stability of ceramic resistors.

3. **Monitoring Systems**: Wearable health monitors and other patient monitoring systems utilize ceramic resistors for accurate readings.

E. Renewable Energy

As the world shifts towards sustainable energy solutions, ceramic resistors are increasingly used in:

1. **Solar Power Systems**: Inverters and power management systems in solar panels rely on ceramic resistors for efficient operation.

2. **Wind Energy Applications**: Wind turbines utilize ceramic resistors in their control systems to ensure optimal performance.

3. **Energy Storage Solutions**: Battery management systems in energy storage devices benefit from the high voltage tolerance of ceramic resistors.

F. Industrial Automation

In industrial automation, ceramic resistors are essential for:

1. **Robotics**: Control circuits in robotic systems require reliable components to ensure precise movements.

2. **Process Control Systems**: Ceramic resistors are used in systems that monitor and control manufacturing processes.

3. **Manufacturing Equipment**: Equipment used in production lines relies on ceramic resistors for power management and safety mechanisms.

IV. Detailed Application Scenarios

A. Electronics and Electrical Engineering

1. **Circuit Protection**: Ceramic resistors are used to protect sensitive components from voltage spikes and surges.

2. **Signal Conditioning**: They help in filtering and conditioning signals in various electronic devices.

3. **Power Management**: Ceramic resistors play a crucial role in managing power distribution in complex electronic systems.

B. Automotive Industry

1. **Battery Management Systems**: Ceramic resistors are essential for monitoring and managing battery performance in electric vehicles.

2. **Sensor Applications**: They are used in various sensors to ensure accurate readings and reliable performance.

3. **Power Distribution**: Ceramic resistors help manage power distribution in automotive electrical systems.

C. Aerospace and Defense

1. **Navigation Systems**: Ceramic resistors are critical in ensuring the accuracy and reliability of navigation systems in aircraft.

2. **Communication Systems**: They help maintain signal integrity in military communication devices.

3. **Environmental Control Systems**: Ceramic resistors are used in systems that regulate temperature and pressure in aerospace applications.

D. Medical Devices

1. **Imaging Systems**: Ceramic resistors are used in imaging equipment to ensure accurate and reliable performance.

2. **Implantable Devices**: They are essential for the functionality of various implantable medical devices.

3. **Wearable Health Monitors**: Ceramic resistors help ensure accurate readings in wearable health monitoring devices.

E. Renewable Energy

1. **Inverters**: Ceramic resistors are used in inverters to convert DC to AC power efficiently.

2. **Grid Integration**: They play a crucial role in integrating renewable energy sources into the power grid.

3. **Battery Management**: Ceramic resistors are essential for monitoring and managing battery performance in renewable energy systems.

F. Industrial Automation

1. **Control Circuits**: Ceramic resistors are used in control circuits to ensure precise operation of automated systems.

2. **Feedback Systems**: They help in providing feedback for various automated processes.

3. **Safety Mechanisms**: Ceramic resistors are critical in safety systems that protect equipment and personnel in industrial settings.

V. Future Trends and Innovations

A. Advancements in Ceramic Materials

Research is ongoing to develop new ceramic materials that enhance the performance of ceramic resistors, making them even more suitable for high-demand applications.

B. Miniaturization and Integration

As electronic devices become smaller and more integrated, the demand for miniaturized ceramic resistors is expected to grow, leading to innovations in design and manufacturing.

C. Sustainability and Eco-Friendly Practices

The push for sustainability is driving the development of eco-friendly ceramic materials and manufacturing processes, making ceramic resistors more environmentally friendly.

D. Emerging Markets and Applications

New markets, such as the Internet of Things (IoT) and smart devices, are creating additional opportunities for ceramic resistors, expanding their application scenarios.

VI. Conclusion

In summary, ceramic resistors play a crucial role in various industries, from electronics and automotive to aerospace and medical devices. Their unique characteristics, such as high temperature resistance, stability, and low noise, make them indispensable in modern technology. As industries continue to evolve, the importance of ceramic resistors will only grow, paving the way for future developments and innovations in this essential component.

VII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

4. Relevant Books and Articles

This blog post provides a comprehensive overview of the application scenarios of ceramic resistors across various industries, highlighting their significance and future potential.

What Industries Are the Application Scenarios of Ceramic Resistors Included In?

I. Introduction

Ceramic resistors are a vital component in modern electronic devices, known for their durability and reliability. These resistors are made from ceramic materials, which provide excellent thermal stability and electrical insulation. As technology continues to advance, the demand for high-performance components like ceramic resistors has surged, making them indispensable in various industries. This blog post will explore the characteristics of ceramic resistors and their application scenarios across multiple sectors, including electronics, automotive, aerospace, medical devices, renewable energy, and industrial automation.

II. Characteristics of Ceramic Resistors

A. Composition and Manufacturing Process

Ceramic resistors are typically composed of a mixture of metal oxides, which are processed and sintered at high temperatures to form a solid ceramic body. This manufacturing process results in a resistor that can withstand extreme conditions, making it suitable for various applications.

B. Key Properties

1. **High Temperature Resistance**: Ceramic resistors can operate at elevated temperatures without degrading, making them ideal for applications in harsh environments.

2. **Stability and Reliability**: These resistors exhibit minimal drift in resistance values over time, ensuring consistent performance in critical applications.

3. **Low Noise Characteristics**: Ceramic resistors produce less electrical noise compared to other resistor types, which is crucial in sensitive electronic circuits.

4. **High Voltage Tolerance**: They can handle high voltage levels, making them suitable for power applications where other resistors might fail.

C. Comparison with Other Types of Resistors

Compared to carbon film or metal film resistors, ceramic resistors offer superior thermal stability and voltage handling capabilities. While other resistors may be more cost-effective for low-power applications, ceramic resistors are preferred in high-performance scenarios where reliability is paramount.

III. Overview of Industries Utilizing Ceramic Resistors

A. Electronics and Electrical Engineering

Ceramic resistors are widely used in the electronics and electrical engineering sectors. They play a crucial role in:

1. **Consumer Electronics**: Devices such as smartphones, tablets, and laptops rely on ceramic resistors for circuit protection and signal conditioning.

2. **Industrial Equipment**: Heavy machinery and industrial automation systems utilize ceramic resistors for power management and control circuits.

3. **Telecommunications**: In communication devices, ceramic resistors help maintain signal integrity and manage power distribution.

B. Automotive Industry

The automotive industry has seen a significant shift towards electric and hybrid vehicles, increasing the demand for ceramic resistors in:

1. **Electric Vehicles**: These vehicles require robust components that can handle high voltages and temperatures, making ceramic resistors ideal for battery management systems.

2. **Engine Control Units (ECUs)**: Ceramic resistors are used in ECUs to ensure precise control of engine functions and emissions.

3. **Safety Systems**: Advanced safety features, such as anti-lock braking systems (ABS) and airbag deployment systems, rely on the reliability of ceramic resistors.

C. Aerospace and Defense

In the aerospace and defense sectors, where reliability is critical, ceramic resistors are employed in:

1. **Avionics**: Navigation and communication systems in aircraft depend on ceramic resistors for stable performance.

2. **Military Applications**: Equipment used in military operations requires components that can withstand extreme conditions, making ceramic resistors a preferred choice.

3. **Space Exploration**: In spacecraft, ceramic resistors are used in various systems, including power management and environmental control.

D. Medical Devices

The medical field relies on ceramic resistors for:

1. **Diagnostic Equipment**: Devices such as MRI machines and ultrasound equipment require precise and reliable components.

2. **Therapeutic Devices**: Equipment used for treatment, such as radiation therapy machines, benefits from the stability of ceramic resistors.

3. **Monitoring Systems**: Wearable health monitors and other patient monitoring systems utilize ceramic resistors for accurate readings.

E. Renewable Energy

As the world shifts towards sustainable energy solutions, ceramic resistors are increasingly used in:

1. **Solar Power Systems**: Inverters and power management systems in solar panels rely on ceramic resistors for efficient operation.

2. **Wind Energy Applications**: Wind turbines utilize ceramic resistors in their control systems to ensure optimal performance.

3. **Energy Storage Solutions**: Battery management systems in energy storage devices benefit from the high voltage tolerance of ceramic resistors.

F. Industrial Automation

In industrial automation, ceramic resistors are essential for:

1. **Robotics**: Control circuits in robotic systems require reliable components to ensure precise movements.

2. **Process Control Systems**: Ceramic resistors are used in systems that monitor and control manufacturing processes.

3. **Manufacturing Equipment**: Equipment used in production lines relies on ceramic resistors for power management and safety mechanisms.

IV. Detailed Application Scenarios

A. Electronics and Electrical Engineering

1. **Circuit Protection**: Ceramic resistors are used to protect sensitive components from voltage spikes and surges.

2. **Signal Conditioning**: They help in filtering and conditioning signals in various electronic devices.

3. **Power Management**: Ceramic resistors play a crucial role in managing power distribution in complex electronic systems.

B. Automotive Industry

1. **Battery Management Systems**: Ceramic resistors are essential for monitoring and managing battery performance in electric vehicles.

2. **Sensor Applications**: They are used in various sensors to ensure accurate readings and reliable performance.

3. **Power Distribution**: Ceramic resistors help manage power distribution in automotive electrical systems.

C. Aerospace and Defense

1. **Navigation Systems**: Ceramic resistors are critical in ensuring the accuracy and reliability of navigation systems in aircraft.

2. **Communication Systems**: They help maintain signal integrity in military communication devices.

3. **Environmental Control Systems**: Ceramic resistors are used in systems that regulate temperature and pressure in aerospace applications.

D. Medical Devices

1. **Imaging Systems**: Ceramic resistors are used in imaging equipment to ensure accurate and reliable performance.

2. **Implantable Devices**: They are essential for the functionality of various implantable medical devices.

3. **Wearable Health Monitors**: Ceramic resistors help ensure accurate readings in wearable health monitoring devices.

E. Renewable Energy

1. **Inverters**: Ceramic resistors are used in inverters to convert DC to AC power efficiently.

2. **Grid Integration**: They play a crucial role in integrating renewable energy sources into the power grid.

3. **Battery Management**: Ceramic resistors are essential for monitoring and managing battery performance in renewable energy systems.

F. Industrial Automation

1. **Control Circuits**: Ceramic resistors are used in control circuits to ensure precise operation of automated systems.

2. **Feedback Systems**: They help in providing feedback for various automated processes.

3. **Safety Mechanisms**: Ceramic resistors are critical in safety systems that protect equipment and personnel in industrial settings.

V. Future Trends and Innovations

A. Advancements in Ceramic Materials

Research is ongoing to develop new ceramic materials that enhance the performance of ceramic resistors, making them even more suitable for high-demand applications.

B. Miniaturization and Integration

As electronic devices become smaller and more integrated, the demand for miniaturized ceramic resistors is expected to grow, leading to innovations in design and manufacturing.

C. Sustainability and Eco-Friendly Practices

The push for sustainability is driving the development of eco-friendly ceramic materials and manufacturing processes, making ceramic resistors more environmentally friendly.

D. Emerging Markets and Applications

New markets, such as the Internet of Things (IoT) and smart devices, are creating additional opportunities for ceramic resistors, expanding their application scenarios.

VI. Conclusion

In summary, ceramic resistors play a crucial role in various industries, from electronics and automotive to aerospace and medical devices. Their unique characteristics, such as high temperature resistance, stability, and low noise, make them indispensable in modern technology. As industries continue to evolve, the importance of ceramic resistors will only grow, paving the way for future developments and innovations in this essential component.

VII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

4. Relevant Books and Articles

This blog post provides a comprehensive overview of the application scenarios of ceramic resistors across various industries, highlighting their significance and future potential.