What are the Product Features of Neutral Point Grounding Resistors?

I. Introduction

A. Definition of Neutral Point Grounding Resistors

Neutral Point Grounding Resistors (NPGRs) are critical components in electrical systems, designed to connect the neutral point of a transformer or generator to the ground through a resistor. This connection helps manage fault currents and enhances the safety and reliability of electrical installations.

B. Importance of Grounding in Electrical Systems

Grounding is a fundamental aspect of electrical engineering, providing a reference point for voltage levels and a safe path for fault currents. Proper grounding minimizes the risk of electrical shock, equipment damage, and fire hazards. Neutral point grounding, in particular, plays a vital role in stabilizing voltage levels during unbalanced load conditions and fault scenarios.

C. Purpose of the Article

This article aims to explore the key features of Neutral Point Grounding Resistors, their benefits, and their applications in various electrical systems. Understanding these features is essential for selecting the right NPGR for specific needs, ensuring optimal performance and safety.

II. Overview of Neutral Point Grounding

A. Explanation of Neutral Point Grounding

Neutral point grounding involves connecting the neutral point of a three-phase system to the ground. This connection can be achieved through various methods, including solid grounding, ungrounded systems, and resistance grounding. Each method has its advantages and disadvantages, depending on the application and system requirements.

B. Types of Grounding Systems

1. **Solid Grounding**: In solid grounding, the neutral point is directly connected to the ground without any resistance. This method provides excellent fault current protection but can lead to high fault currents that may damage equipment.

2. **Ungrounded Systems**: In ungrounded systems, the neutral point is not connected to the ground. This approach allows for continued operation during a single-phase fault but can lead to overvoltages and is less safe.

3. **Resistance Grounding**: Resistance grounding connects the neutral point to the ground through a resistor. This method limits fault currents to a safe level, reducing the risk of equipment damage while maintaining system stability.

C. Role of Neutral Point Grounding Resistors in Electrical Systems

Neutral Point Grounding Resistors play a crucial role in resistance grounding systems. They limit the magnitude of fault currents, protect equipment from damage, and enhance the overall safety of electrical installations. By controlling fault currents, NPGRs help maintain system reliability and reduce the risk of electrical hazards.

III. Key Features of Neutral Point Grounding Resistors

A. Resistance Value

1. **Importance of Resistance Value**: The resistance value of an NPGR is critical in determining the maximum fault current that can flow during a fault condition. A properly selected resistance value ensures that fault currents remain within safe limits, protecting equipment and personnel.

2. **Selection Criteria for Resistance Value**: When selecting the resistance value, factors such as system voltage, fault current levels, and equipment ratings must be considered. Engineers often use calculations and simulations to determine the optimal resistance value for specific applications.

B. Power Rating

1. **Definition and Importance**: The power rating of an NPGR indicates the maximum amount of power it can dissipate without overheating. This rating is essential for ensuring that the resistor can handle fault conditions without failure.

2. **How Power Rating Affects Performance**: A higher power rating allows the NPGR to manage larger fault currents, enhancing system protection. However, selecting a resistor with an excessively high power rating can lead to unnecessary costs and space requirements.

C. Temperature Rating

1. **Significance of Temperature Ratings**: Temperature ratings indicate the maximum operating temperature of the NPGR. This feature is crucial for ensuring reliable performance in various environmental conditions.

2. **Impact of Environmental Conditions**: High ambient temperatures can affect the performance and lifespan of NPGRs. Therefore, selecting a resistor with an appropriate temperature rating for the installation environment is essential.

D. Insulation Class

1. **Explanation of Insulation Class**: The insulation class of an NPGR refers to its ability to withstand electrical stress without failure. Different insulation classes are designed for various voltage levels and environmental conditions.

2. **Importance in Safety and Performance**: Proper insulation is vital for preventing electrical breakdown and ensuring the safety of personnel and equipment. Selecting the right insulation class is essential for reliable operation.

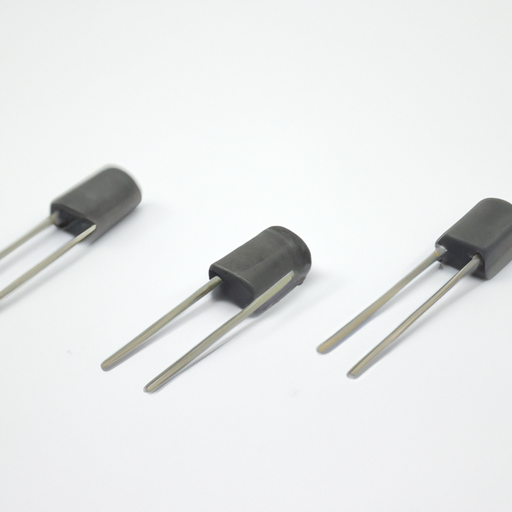

E. Construction Materials

1. **Common Materials Used**: NPGRs are typically constructed from materials such as steel, aluminum, and various insulating compounds. The choice of materials affects the resistor's durability, performance, and cost.

2. **Impact on Durability and Performance**: High-quality materials enhance the lifespan and reliability of NPGRs, making them more effective in protecting electrical systems.

F. Size and Form Factor

1. **Importance of Size in Installation**: The physical size of an NPGR can impact its installation and integration into existing systems. Compact designs may be necessary for space-constrained environments.

2. **Variations in Form Factor**: NPGRs come in various form factors, including rack-mounted, panel-mounted, and standalone units. The choice of form factor should align with the specific installation requirements.

G. Connection Type

1. **Types of Connections Available**: NPGRs can feature different connection types, including terminal connections, busbar connections, and cable connections. The choice of connection type affects installation ease and compatibility with existing systems.

2. **Importance of Compatibility with Existing Systems**: Ensuring that the NPGR is compatible with the existing electrical infrastructure is crucial for seamless integration and optimal performance.

H. Compliance and Standards

1. **Relevant Industry Standards**: NPGRs must comply with various industry standards, such as IEEE, IEC, and UL, to ensure safety and reliability. Compliance with these standards is essential for regulatory approval and market acceptance.

2. **Importance of Compliance for Safety and Reliability**: Adhering to industry standards helps ensure that NPGRs perform as intended, reducing the risk of failures and enhancing overall system safety.

IV. Benefits of Using Neutral Point Grounding Resistors

A. Enhanced System Protection

1. **Limiting Fault Currents**: NPGRs effectively limit fault currents, reducing the risk of equipment damage and enhancing the overall safety of electrical systems.

2. **Reducing Equipment Damage**: By controlling fault currents, NPGRs help protect sensitive equipment from the adverse effects of electrical faults, prolonging their lifespan and reducing maintenance costs.

B. Improved Safety

1. **Protection for Personnel**: NPGRs enhance safety for personnel by minimizing the risk of electrical shock and other hazards associated with electrical faults.

2. **Minimizing Electrical Hazards**: By limiting fault currents and providing a safe path for electrical energy, NPGRs help reduce the likelihood of electrical fires and other hazards.

C. Increased System Reliability

1. **Reducing Downtime**: NPGRs contribute to increased system reliability by minimizing the impact of electrical faults, reducing downtime, and enhancing operational efficiency.

2. **Enhancing Operational Efficiency**: A reliable electrical system allows for smoother operations, leading to improved productivity and reduced operational costs.

D. Cost-Effectiveness

1. **Long-Term Savings**: Investing in NPGRs can lead to long-term savings by reducing equipment damage, maintenance costs, and downtime.

2. **Reduced Maintenance Costs**: With enhanced protection and reliability, NPGRs help lower maintenance costs associated with electrical systems, making them a cost-effective solution.

V. Applications of Neutral Point Grounding Resistors

A. Industrial Applications

1. **Manufacturing Facilities**: NPGRs are commonly used in manufacturing facilities to protect equipment and ensure safe operations in complex electrical systems.

2. **Power Generation Plants**: In power generation plants, NPGRs help manage fault currents and enhance the reliability of electrical systems.

B. Commercial Applications

1. **Office Buildings**: NPGRs are essential in office buildings to ensure the safety and reliability of electrical systems, protecting both personnel and equipment.

2. **Retail Spaces**: In retail environments, NPGRs help maintain operational efficiency and protect sensitive electronic equipment.

C. Utility Applications

1. **Electrical Distribution Networks**: NPGRs play a vital role in electrical distribution networks, helping to manage fault currents and enhance system reliability.

2. **Renewable Energy Systems**: In renewable energy systems, NPGRs help ensure safe and reliable operation, protecting equipment from electrical faults.

VI. Conclusion

A. Recap of Key Features and Benefits

Neutral Point Grounding Resistors are essential components in electrical systems, offering key features such as resistance value, power rating, temperature rating, insulation class, construction materials, size, connection type, and compliance with industry standards. These features contribute to the numerous benefits of NPGRs, including enhanced system protection, improved safety, increased reliability, and cost-effectiveness.

B. Importance of Selecting the Right Neutral Point Grounding Resistor

Selecting the right NPGR is crucial for ensuring optimal performance and safety in electrical systems. Engineers and technicians must carefully consider the specific requirements of their applications to choose the most suitable NPGR.

C. Final Thoughts on the Role of Grounding in Electrical Safety and Reliability

In conclusion, neutral point grounding is a vital aspect of electrical safety and reliability. By understanding the features and benefits of Neutral Point Grounding Resistors, stakeholders can make informed decisions that enhance the safety and performance of their electrical systems.

VII. References

A. Suggested Reading and Resources

1. IEEE Standards for Grounding of Electrical Systems

2. IEC Guidelines for Electrical Safety

3. UL Standards for Electrical Equipment

B. Industry Standards and Guidelines

1. IEEE 142 - Grounding of Industrial and Commercial Power Systems

2. IEC 60364 - Electrical Installations of Buildings

3. UL 467 - Grounding and Bonding Equipment

By understanding the critical features and benefits of Neutral Point Grounding Resistors, professionals can ensure the safety, reliability, and efficiency of their electrical systems.

What are the Product Features of Neutral Point Grounding Resistors?

I. Introduction

A. Definition of Neutral Point Grounding Resistors

Neutral Point Grounding Resistors (NPGRs) are critical components in electrical systems, designed to connect the neutral point of a transformer or generator to the ground through a resistor. This connection helps manage fault currents and enhances the safety and reliability of electrical installations.

B. Importance of Grounding in Electrical Systems

Grounding is a fundamental aspect of electrical engineering, providing a reference point for voltage levels and a safe path for fault currents. Proper grounding minimizes the risk of electrical shock, equipment damage, and fire hazards. Neutral point grounding, in particular, plays a vital role in stabilizing voltage levels during unbalanced load conditions and fault scenarios.

C. Purpose of the Article

This article aims to explore the key features of Neutral Point Grounding Resistors, their benefits, and their applications in various electrical systems. Understanding these features is essential for selecting the right NPGR for specific needs, ensuring optimal performance and safety.

II. Overview of Neutral Point Grounding

A. Explanation of Neutral Point Grounding

Neutral point grounding involves connecting the neutral point of a three-phase system to the ground. This connection can be achieved through various methods, including solid grounding, ungrounded systems, and resistance grounding. Each method has its advantages and disadvantages, depending on the application and system requirements.

B. Types of Grounding Systems

1. **Solid Grounding**: In solid grounding, the neutral point is directly connected to the ground without any resistance. This method provides excellent fault current protection but can lead to high fault currents that may damage equipment.

2. **Ungrounded Systems**: In ungrounded systems, the neutral point is not connected to the ground. This approach allows for continued operation during a single-phase fault but can lead to overvoltages and is less safe.

3. **Resistance Grounding**: Resistance grounding connects the neutral point to the ground through a resistor. This method limits fault currents to a safe level, reducing the risk of equipment damage while maintaining system stability.

C. Role of Neutral Point Grounding Resistors in Electrical Systems

Neutral Point Grounding Resistors play a crucial role in resistance grounding systems. They limit the magnitude of fault currents, protect equipment from damage, and enhance the overall safety of electrical installations. By controlling fault currents, NPGRs help maintain system reliability and reduce the risk of electrical hazards.

III. Key Features of Neutral Point Grounding Resistors

A. Resistance Value

1. **Importance of Resistance Value**: The resistance value of an NPGR is critical in determining the maximum fault current that can flow during a fault condition. A properly selected resistance value ensures that fault currents remain within safe limits, protecting equipment and personnel.

2. **Selection Criteria for Resistance Value**: When selecting the resistance value, factors such as system voltage, fault current levels, and equipment ratings must be considered. Engineers often use calculations and simulations to determine the optimal resistance value for specific applications.

B. Power Rating

1. **Definition and Importance**: The power rating of an NPGR indicates the maximum amount of power it can dissipate without overheating. This rating is essential for ensuring that the resistor can handle fault conditions without failure.

2. **How Power Rating Affects Performance**: A higher power rating allows the NPGR to manage larger fault currents, enhancing system protection. However, selecting a resistor with an excessively high power rating can lead to unnecessary costs and space requirements.

C. Temperature Rating

1. **Significance of Temperature Ratings**: Temperature ratings indicate the maximum operating temperature of the NPGR. This feature is crucial for ensuring reliable performance in various environmental conditions.

2. **Impact of Environmental Conditions**: High ambient temperatures can affect the performance and lifespan of NPGRs. Therefore, selecting a resistor with an appropriate temperature rating for the installation environment is essential.

D. Insulation Class

1. **Explanation of Insulation Class**: The insulation class of an NPGR refers to its ability to withstand electrical stress without failure. Different insulation classes are designed for various voltage levels and environmental conditions.

2. **Importance in Safety and Performance**: Proper insulation is vital for preventing electrical breakdown and ensuring the safety of personnel and equipment. Selecting the right insulation class is essential for reliable operation.

E. Construction Materials

1. **Common Materials Used**: NPGRs are typically constructed from materials such as steel, aluminum, and various insulating compounds. The choice of materials affects the resistor's durability, performance, and cost.

2. **Impact on Durability and Performance**: High-quality materials enhance the lifespan and reliability of NPGRs, making them more effective in protecting electrical systems.

F. Size and Form Factor

1. **Importance of Size in Installation**: The physical size of an NPGR can impact its installation and integration into existing systems. Compact designs may be necessary for space-constrained environments.

2. **Variations in Form Factor**: NPGRs come in various form factors, including rack-mounted, panel-mounted, and standalone units. The choice of form factor should align with the specific installation requirements.

G. Connection Type

1. **Types of Connections Available**: NPGRs can feature different connection types, including terminal connections, busbar connections, and cable connections. The choice of connection type affects installation ease and compatibility with existing systems.

2. **Importance of Compatibility with Existing Systems**: Ensuring that the NPGR is compatible with the existing electrical infrastructure is crucial for seamless integration and optimal performance.

H. Compliance and Standards

1. **Relevant Industry Standards**: NPGRs must comply with various industry standards, such as IEEE, IEC, and UL, to ensure safety and reliability. Compliance with these standards is essential for regulatory approval and market acceptance.

2. **Importance of Compliance for Safety and Reliability**: Adhering to industry standards helps ensure that NPGRs perform as intended, reducing the risk of failures and enhancing overall system safety.

IV. Benefits of Using Neutral Point Grounding Resistors

A. Enhanced System Protection

1. **Limiting Fault Currents**: NPGRs effectively limit fault currents, reducing the risk of equipment damage and enhancing the overall safety of electrical systems.

2. **Reducing Equipment Damage**: By controlling fault currents, NPGRs help protect sensitive equipment from the adverse effects of electrical faults, prolonging their lifespan and reducing maintenance costs.

B. Improved Safety

1. **Protection for Personnel**: NPGRs enhance safety for personnel by minimizing the risk of electrical shock and other hazards associated with electrical faults.

2. **Minimizing Electrical Hazards**: By limiting fault currents and providing a safe path for electrical energy, NPGRs help reduce the likelihood of electrical fires and other hazards.

C. Increased System Reliability

1. **Reducing Downtime**: NPGRs contribute to increased system reliability by minimizing the impact of electrical faults, reducing downtime, and enhancing operational efficiency.

2. **Enhancing Operational Efficiency**: A reliable electrical system allows for smoother operations, leading to improved productivity and reduced operational costs.

D. Cost-Effectiveness

1. **Long-Term Savings**: Investing in NPGRs can lead to long-term savings by reducing equipment damage, maintenance costs, and downtime.

2. **Reduced Maintenance Costs**: With enhanced protection and reliability, NPGRs help lower maintenance costs associated with electrical systems, making them a cost-effective solution.

V. Applications of Neutral Point Grounding Resistors

A. Industrial Applications

1. **Manufacturing Facilities**: NPGRs are commonly used in manufacturing facilities to protect equipment and ensure safe operations in complex electrical systems.

2. **Power Generation Plants**: In power generation plants, NPGRs help manage fault currents and enhance the reliability of electrical systems.

B. Commercial Applications

1. **Office Buildings**: NPGRs are essential in office buildings to ensure the safety and reliability of electrical systems, protecting both personnel and equipment.

2. **Retail Spaces**: In retail environments, NPGRs help maintain operational efficiency and protect sensitive electronic equipment.

C. Utility Applications

1. **Electrical Distribution Networks**: NPGRs play a vital role in electrical distribution networks, helping to manage fault currents and enhance system reliability.

2. **Renewable Energy Systems**: In renewable energy systems, NPGRs help ensure safe and reliable operation, protecting equipment from electrical faults.

VI. Conclusion

A. Recap of Key Features and Benefits

Neutral Point Grounding Resistors are essential components in electrical systems, offering key features such as resistance value, power rating, temperature rating, insulation class, construction materials, size, connection type, and compliance with industry standards. These features contribute to the numerous benefits of NPGRs, including enhanced system protection, improved safety, increased reliability, and cost-effectiveness.

B. Importance of Selecting the Right Neutral Point Grounding Resistor

Selecting the right NPGR is crucial for ensuring optimal performance and safety in electrical systems. Engineers and technicians must carefully consider the specific requirements of their applications to choose the most suitable NPGR.

C. Final Thoughts on the Role of Grounding in Electrical Safety and Reliability

In conclusion, neutral point grounding is a vital aspect of electrical safety and reliability. By understanding the features and benefits of Neutral Point Grounding Resistors, stakeholders can make informed decisions that enhance the safety and performance of their electrical systems.

VII. References

A. Suggested Reading and Resources

1. IEEE Standards for Grounding of Electrical Systems

2. IEC Guidelines for Electrical Safety

3. UL Standards for Electrical Equipment

B. Industry Standards and Guidelines

1. IEEE 142 - Grounding of Industrial and Commercial Power Systems

2. IEC 60364 - Electrical Installations of Buildings

3. UL 467 - Grounding and Bonding Equipment

By understanding the critical features and benefits of Neutral Point Grounding Resistors, professionals can ensure the safety, reliability, and efficiency of their electrical systems.