What are the Popular Power Product Types of Resistors?

I. Introduction

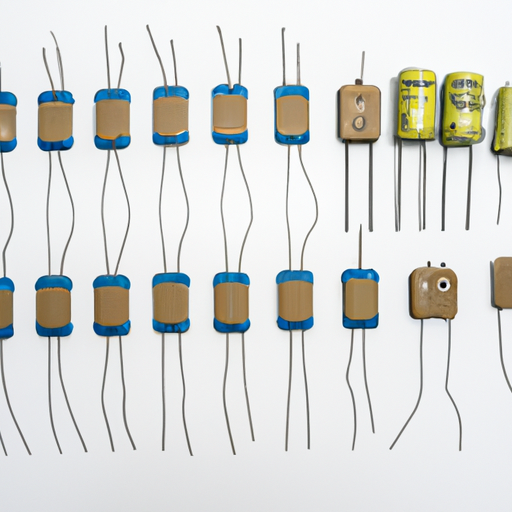

Resistors are fundamental components in electrical and electronic circuits, serving the essential function of limiting current flow and dividing voltages. They play a crucial role in ensuring that circuits operate safely and effectively, protecting sensitive components from excessive current. Understanding the various types of resistors, particularly in terms of their power ratings, is vital for engineers and hobbyists alike. This blog post will explore the popular power product types of resistors, their characteristics, applications, and the factors influencing their selection.

II. Understanding Resistor Power Ratings

A. Definition of Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without being damaged. It is typically measured in watts (W) and is a critical specification that determines how a resistor can be used in a circuit. Exceeding the power rating can lead to overheating, failure, or even catastrophic failure of the resistor.

B. Factors Influencing Power Ratings

Several factors influence the power ratings of resistors:

1. **Material Composition**: The materials used in the construction of a resistor significantly affect its power handling capabilities. For instance, wirewound resistors can handle higher power levels due to their construction compared to carbon composition resistors.

2. **Size and Form Factor**: Larger resistors generally have higher power ratings because they can dissipate heat more effectively. The physical size and shape of the resistor also play a role in its ability to manage heat.

3. **Heat Dissipation Mechanisms**: Resistors dissipate heat through conduction, convection, and radiation. The efficiency of these mechanisms can vary based on the resistor's design and the environment in which it operates.

C. Importance of Selecting the Right Power Rating

Choosing the appropriate power rating for a resistor is crucial for the reliability and longevity of electronic circuits. A resistor with an inadequate power rating can fail, leading to circuit malfunction and potential damage to other components. Therefore, understanding the power requirements of a circuit is essential for selecting the right resistor.

III. Types of Resistors Based on Power Ratings

Resistors can be categorized based on their power ratings into three main types: low-power, medium-power, and high-power resistors.

A. Low-Power Resistors

1. **Characteristics**: Low-power resistors typically have power ratings of up to 1 watt. They are usually small in size and are made from materials like carbon or metal film.

2. **Common Applications**: These resistors are commonly used in low-power applications such as signal processing, audio equipment, and consumer electronics.

3. **Examples**: Carbon composition resistors and metal film resistors are popular examples of low-power resistors.

B. Medium-Power Resistors

1. **Characteristics**: Medium-power resistors have power ratings ranging from 1 watt to 10 watts. They are larger than low-power resistors and can handle more heat.

2. **Common Applications**: These resistors are often used in power supplies, amplifiers, and other applications where moderate power dissipation is required.

3. **Examples**: Wirewound resistors and thick film resistors are typical examples of medium-power resistors.

C. High-Power Resistors

1. **Characteristics**: High-power resistors are designed to handle power ratings above 10 watts, often reaching hundreds of watts. They are built to dissipate heat effectively and are usually larger in size.

2. **Common Applications**: These resistors are used in high-power circuits, such as industrial equipment, power amplifiers, and motor control systems.

3. **Examples**: High-power wirewound resistors and ceramic resistors are common examples of high-power resistors.

IV. Popular Power Product Types of Resistors

A. Carbon Composition Resistors

1. **Overview**: Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their low cost and simplicity.

2. **Power Ratings and Applications**: Typically available in low-power ratings, these resistors are suitable for applications where precision is not critical, such as in general-purpose circuits.

B. Metal Film Resistors

1. **Overview**: Metal film resistors are constructed using a thin film of metal deposited on a ceramic substrate. They offer better stability and tolerance compared to carbon composition resistors.

2. **Power Ratings and Applications**: These resistors are available in low to medium power ratings and are commonly used in precision applications, such as audio equipment and instrumentation.

C. Wirewound Resistors

1. **Overview**: Wirewound resistors consist of a wire wound around a ceramic or fiberglass core. They are known for their high power handling capabilities and stability.

2. **Power Ratings and Applications**: Available in medium to high power ratings, wirewound resistors are used in power supplies, amplifiers, and other high-power applications.

D. Thick Film Resistors

1. **Overview**: Thick film resistors are made by printing a resistive paste onto a ceramic substrate. They are versatile and can be produced in various shapes and sizes.

2. **Power Ratings and Applications**: These resistors are available in medium power ratings and are commonly used in automotive and industrial applications.

E. Thin Film Resistors

1. **Overview**: Thin film resistors are similar to thick film resistors but are made with a thinner layer of resistive material. They offer higher precision and stability.

2. **Power Ratings and Applications**: Typically available in low to medium power ratings, thin film resistors are used in high-precision applications, such as medical devices and aerospace electronics.

F. Ceramic Resistors

1. **Overview**: Ceramic resistors are made from a ceramic material that can withstand high temperatures and power levels. They are known for their durability and reliability.

2. **Power Ratings and Applications**: These resistors are available in high power ratings and are commonly used in industrial applications, power electronics, and high-voltage circuits.

V. Specialized Resistor Types

A. Power Resistors

1. **Overview**: Power resistors are designed specifically for high-power applications. They are built to handle significant amounts of heat and current.

2. **Applications in High-Power Circuits**: These resistors are used in applications such as motor control, power supplies, and load testing.

B. Current Sensing Resistors

1. **Overview**: Current sensing resistors are low-resistance resistors used to measure current flow in a circuit. They are often used in feedback systems.

2. **Applications in Monitoring and Control**: These resistors are commonly found in power management systems, battery management systems, and automotive applications.

C. High Voltage Resistors

1. **Overview**: High voltage resistors are designed to operate safely at high voltages. They are constructed to prevent arcing and breakdown.

2. **Applications in High Voltage Systems**: These resistors are used in applications such as power transmission, high-voltage testing, and electrical insulation.

VI. Factors to Consider When Choosing Resistors

When selecting resistors for a specific application, several factors should be considered:

A. Application Requirements

Understanding the specific requirements of the application, including voltage, current, and power dissipation, is crucial for selecting the right resistor.

B. Environmental Conditions

The operating environment, including temperature, humidity, and exposure to chemicals, can affect the performance and reliability of resistors.

C. Cost Considerations

Budget constraints may influence the choice of resistors, but it is essential to balance cost with performance and reliability.

D. Availability and Sourcing

The availability of specific resistor types and their sourcing can impact project timelines and costs. It is essential to consider lead times and supplier reliability.

VII. Conclusion

In conclusion, resistors are vital components in electrical circuits, and understanding their power ratings and types is essential for effective circuit design. From low-power carbon composition resistors to high-power wirewound and ceramic resistors, each type has its unique characteristics and applications. As technology advances, the development of new resistor types and materials will continue to shape the future of electronic design. Selecting the right resistor is crucial for ensuring the reliability and performance of electronic systems, making it a fundamental aspect of circuit design.

VIII. References

- Academic Journals on Electrical Engineering

- Industry Standards for Resistor Specifications

- Manufacturer Specifications and Datasheets

This blog post provides a comprehensive overview of the popular power product types of resistors, their characteristics, applications, and considerations for selection, making it a valuable resource for anyone involved in electronics.

What are the Popular Power Product Types of Resistors?

I. Introduction

Resistors are fundamental components in electrical and electronic circuits, serving the essential function of limiting current flow and dividing voltages. They play a crucial role in ensuring that circuits operate safely and effectively, protecting sensitive components from excessive current. Understanding the various types of resistors, particularly in terms of their power ratings, is vital for engineers and hobbyists alike. This blog post will explore the popular power product types of resistors, their characteristics, applications, and the factors influencing their selection.

II. Understanding Resistor Power Ratings

A. Definition of Power Rating

The power rating of a resistor indicates the maximum amount of power it can dissipate without being damaged. It is typically measured in watts (W) and is a critical specification that determines how a resistor can be used in a circuit. Exceeding the power rating can lead to overheating, failure, or even catastrophic failure of the resistor.

B. Factors Influencing Power Ratings

Several factors influence the power ratings of resistors:

1. **Material Composition**: The materials used in the construction of a resistor significantly affect its power handling capabilities. For instance, wirewound resistors can handle higher power levels due to their construction compared to carbon composition resistors.

2. **Size and Form Factor**: Larger resistors generally have higher power ratings because they can dissipate heat more effectively. The physical size and shape of the resistor also play a role in its ability to manage heat.

3. **Heat Dissipation Mechanisms**: Resistors dissipate heat through conduction, convection, and radiation. The efficiency of these mechanisms can vary based on the resistor's design and the environment in which it operates.

C. Importance of Selecting the Right Power Rating

Choosing the appropriate power rating for a resistor is crucial for the reliability and longevity of electronic circuits. A resistor with an inadequate power rating can fail, leading to circuit malfunction and potential damage to other components. Therefore, understanding the power requirements of a circuit is essential for selecting the right resistor.

III. Types of Resistors Based on Power Ratings

Resistors can be categorized based on their power ratings into three main types: low-power, medium-power, and high-power resistors.

A. Low-Power Resistors

1. **Characteristics**: Low-power resistors typically have power ratings of up to 1 watt. They are usually small in size and are made from materials like carbon or metal film.

2. **Common Applications**: These resistors are commonly used in low-power applications such as signal processing, audio equipment, and consumer electronics.

3. **Examples**: Carbon composition resistors and metal film resistors are popular examples of low-power resistors.

B. Medium-Power Resistors

1. **Characteristics**: Medium-power resistors have power ratings ranging from 1 watt to 10 watts. They are larger than low-power resistors and can handle more heat.

2. **Common Applications**: These resistors are often used in power supplies, amplifiers, and other applications where moderate power dissipation is required.

3. **Examples**: Wirewound resistors and thick film resistors are typical examples of medium-power resistors.

C. High-Power Resistors

1. **Characteristics**: High-power resistors are designed to handle power ratings above 10 watts, often reaching hundreds of watts. They are built to dissipate heat effectively and are usually larger in size.

2. **Common Applications**: These resistors are used in high-power circuits, such as industrial equipment, power amplifiers, and motor control systems.

3. **Examples**: High-power wirewound resistors and ceramic resistors are common examples of high-power resistors.

IV. Popular Power Product Types of Resistors

A. Carbon Composition Resistors

1. **Overview**: Carbon composition resistors are made from a mixture of carbon particles and a binding resin. They are known for their low cost and simplicity.

2. **Power Ratings and Applications**: Typically available in low-power ratings, these resistors are suitable for applications where precision is not critical, such as in general-purpose circuits.

B. Metal Film Resistors

1. **Overview**: Metal film resistors are constructed using a thin film of metal deposited on a ceramic substrate. They offer better stability and tolerance compared to carbon composition resistors.

2. **Power Ratings and Applications**: These resistors are available in low to medium power ratings and are commonly used in precision applications, such as audio equipment and instrumentation.

C. Wirewound Resistors

1. **Overview**: Wirewound resistors consist of a wire wound around a ceramic or fiberglass core. They are known for their high power handling capabilities and stability.

2. **Power Ratings and Applications**: Available in medium to high power ratings, wirewound resistors are used in power supplies, amplifiers, and other high-power applications.

D. Thick Film Resistors

1. **Overview**: Thick film resistors are made by printing a resistive paste onto a ceramic substrate. They are versatile and can be produced in various shapes and sizes.

2. **Power Ratings and Applications**: These resistors are available in medium power ratings and are commonly used in automotive and industrial applications.

E. Thin Film Resistors

1. **Overview**: Thin film resistors are similar to thick film resistors but are made with a thinner layer of resistive material. They offer higher precision and stability.

2. **Power Ratings and Applications**: Typically available in low to medium power ratings, thin film resistors are used in high-precision applications, such as medical devices and aerospace electronics.

F. Ceramic Resistors

1. **Overview**: Ceramic resistors are made from a ceramic material that can withstand high temperatures and power levels. They are known for their durability and reliability.

2. **Power Ratings and Applications**: These resistors are available in high power ratings and are commonly used in industrial applications, power electronics, and high-voltage circuits.

V. Specialized Resistor Types

A. Power Resistors

1. **Overview**: Power resistors are designed specifically for high-power applications. They are built to handle significant amounts of heat and current.

2. **Applications in High-Power Circuits**: These resistors are used in applications such as motor control, power supplies, and load testing.

B. Current Sensing Resistors

1. **Overview**: Current sensing resistors are low-resistance resistors used to measure current flow in a circuit. They are often used in feedback systems.

2. **Applications in Monitoring and Control**: These resistors are commonly found in power management systems, battery management systems, and automotive applications.

C. High Voltage Resistors

1. **Overview**: High voltage resistors are designed to operate safely at high voltages. They are constructed to prevent arcing and breakdown.

2. **Applications in High Voltage Systems**: These resistors are used in applications such as power transmission, high-voltage testing, and electrical insulation.

VI. Factors to Consider When Choosing Resistors

When selecting resistors for a specific application, several factors should be considered:

A. Application Requirements

Understanding the specific requirements of the application, including voltage, current, and power dissipation, is crucial for selecting the right resistor.

B. Environmental Conditions

The operating environment, including temperature, humidity, and exposure to chemicals, can affect the performance and reliability of resistors.

C. Cost Considerations

Budget constraints may influence the choice of resistors, but it is essential to balance cost with performance and reliability.

D. Availability and Sourcing

The availability of specific resistor types and their sourcing can impact project timelines and costs. It is essential to consider lead times and supplier reliability.

VII. Conclusion

In conclusion, resistors are vital components in electrical circuits, and understanding their power ratings and types is essential for effective circuit design. From low-power carbon composition resistors to high-power wirewound and ceramic resistors, each type has its unique characteristics and applications. As technology advances, the development of new resistor types and materials will continue to shape the future of electronic design. Selecting the right resistor is crucial for ensuring the reliability and performance of electronic systems, making it a fundamental aspect of circuit design.

VIII. References

- Academic Journals on Electrical Engineering

- Industry Standards for Resistor Specifications

- Manufacturer Specifications and Datasheets

This blog post provides a comprehensive overview of the popular power product types of resistors, their characteristics, applications, and considerations for selection, making it a valuable resource for anyone involved in electronics.