What Industries Do Washing Machine Capacitor Application Scenarios Include?

I. Introduction

Washing machines are an essential part of modern households, providing convenience and efficiency in laundry care. At the heart of these machines lies a crucial component: the capacitor. Capacitors play a vital role in the operation of washing machines, ensuring they function smoothly and efficiently. This article explores the various industries that utilize washing machine capacitors, their applications, and the significance of these components in enhancing the performance and efficiency of washing machines.

II. Understanding Washing Machine Capacitors

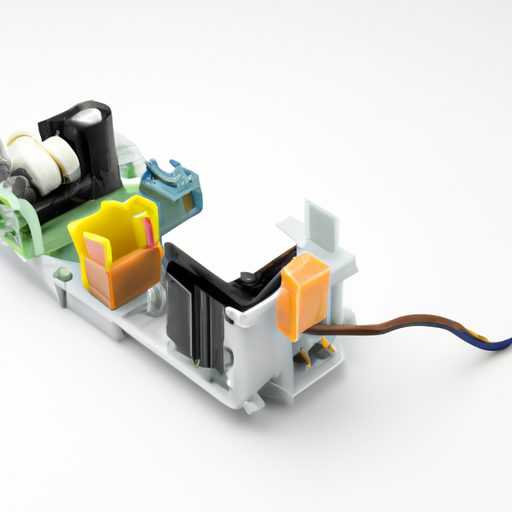

A. Function of Capacitors in Washing Machines

Capacitors are electrical components that store and release energy. In washing machines, they serve several critical functions:

1. **Energy Storage**: Capacitors store electrical energy, which can be released when needed. This is particularly important during the initial startup of the washing machine, where a surge of power is required to get the motor running.

2. **Voltage Regulation**: Capacitors help maintain a stable voltage level within the washing machine, ensuring that the motor and other components receive the appropriate amount of power for optimal performance.

3. **Motor Start and Run Applications**: Capacitors are essential for starting and running the motor in washing machines. They provide the necessary boost of energy to start the motor and help it run efficiently during operation.

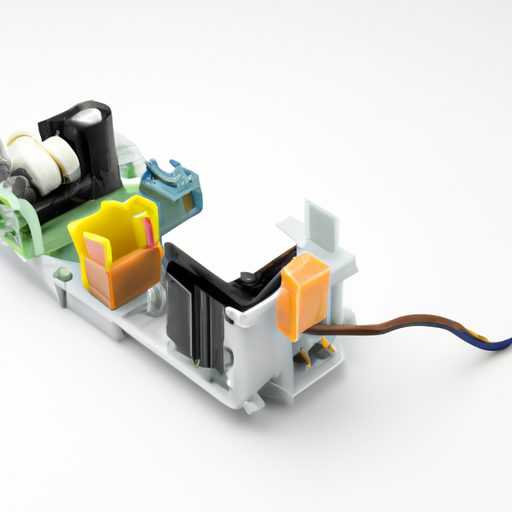

B. Types of Capacitors Used in Washing Machines

There are several types of capacitors used in washing machines, each serving a specific purpose:

1. **Start Capacitors**: These capacitors provide a temporary boost of energy to start the motor. They are typically used in single-phase motors and are designed to disconnect from the circuit once the motor reaches a certain speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit during the entire operation of the motor. They help improve the efficiency and performance of the motor by providing a continuous supply of energy.

3. **Dual Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit. They are commonly used in washing machines with more complex motor systems.

III. Key Industries Utilizing Washing Machine Capacitors

A. Home Appliances Industry

The home appliances industry is the primary sector that utilizes washing machine capacitors. Washing machines are a staple in households, and their performance directly impacts consumer satisfaction. Capacitors play a crucial role in enhancing the efficiency and reliability of washing machines, making them indispensable in this industry.

1. **Overview of the Home Appliance Sector**: The home appliance sector encompasses a wide range of products, including refrigerators, ovens, and washing machines. As consumer demand for energy-efficient and high-performance appliances grows, the role of capacitors becomes increasingly important.

2. **Role of Washing Machines in Households**: Washing machines save time and effort in laundry care, making them a vital appliance in modern homes. The efficiency of these machines is often linked to the quality and performance of their capacitors.

3. **Importance of Capacitors in Enhancing Washing Machine Performance**: High-quality capacitors contribute to the longevity and reliability of washing machines. They help reduce energy consumption, minimize noise, and improve overall performance, making them a key focus for manufacturers in the home appliance industry.

B. Manufacturing Industry

The manufacturing industry is another significant sector that relies on washing machine capacitors. This industry encompasses the production of washing machines and the components that go into them.

1. **Production of Washing Machines**: Manufacturers must ensure that the capacitors used in their washing machines meet specific performance standards. This involves sourcing high-quality capacitors and integrating them into the design of the machines.

2. **Quality Control and Testing of Capacitors**: Quality control is essential in the manufacturing process. Capacitors undergo rigorous testing to ensure they meet safety and performance standards before being used in washing machines.

3. **Innovations in Capacitor Technology for Manufacturing Efficiency**: As technology advances, manufacturers are continually seeking innovative capacitor designs that enhance efficiency and reduce production costs. This includes the development of miniaturized capacitors that take up less space while providing the same level of performance.

C. Electronics Industry

The electronics industry plays a crucial role in the integration of capacitors into washing machines, particularly in the context of smart appliances.

1. **Integration of Capacitors in Electronic Control Systems**: Modern washing machines often feature electronic control systems that rely on capacitors for stable operation. These systems manage various functions, including wash cycles, water levels, and temperature settings.

2. **Role in Smart Washing Machines and IoT Applications**: The rise of smart appliances has led to the integration of capacitors in Internet of Things (IoT) applications. Capacitors help ensure that these devices operate efficiently and reliably, enabling features such as remote control and monitoring.

3. **Advancements in Capacitor Technology for Electronics**: The electronics industry is continually innovating, leading to the development of advanced capacitors that offer improved performance, smaller sizes, and enhanced energy efficiency.

D. Repair and Maintenance Services

Repair and maintenance services are essential for ensuring the longevity and performance of washing machines. Capacitors play a significant role in these services.

1. **Importance of Capacitors in Repair Services**: When washing machines malfunction, capacitors are often among the first components to be checked. A faulty capacitor can lead to issues such as motor failure or erratic operation.

2. **Common Issues Related to Washing Machine Capacitors**: Technicians frequently encounter problems such as capacitor failure, which can result in the washing machine not starting or running inefficiently. Understanding these issues is crucial for effective repairs.

3. **Training and Expertise Required for Technicians**: Technicians must be trained to diagnose and replace faulty capacitors in washing machines. This requires a solid understanding of electrical systems and the specific types of capacitors used in different models.

E. Energy Sector

The energy sector is increasingly focused on energy efficiency, and washing machine capacitors play a vital role in this effort.

1. **Energy Efficiency in Washing Machines**: As consumers become more environmentally conscious, the demand for energy-efficient appliances has grown. Capacitors contribute to this efficiency by optimizing motor performance and reducing energy consumption.

2. **Role of Capacitors in Reducing Energy Consumption**: By improving the efficiency of washing machines, capacitors help reduce overall energy consumption, leading to lower utility bills for consumers and a smaller carbon footprint.

3. **Impact on Sustainability and Environmental Considerations**: The use of energy-efficient washing machines equipped with high-quality capacitors aligns with sustainability goals, making them an attractive option for environmentally conscious consumers.

IV. Emerging Trends and Innovations

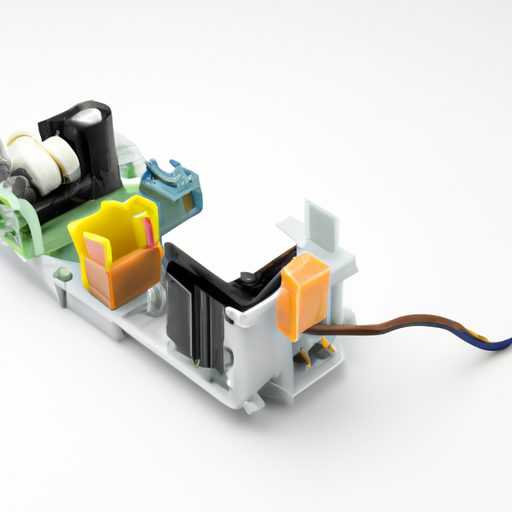

A. Technological Advancements in Capacitor Design

The field of capacitor technology is evolving rapidly, leading to several exciting advancements.

1. **Miniaturization and Efficiency Improvements**: Manufacturers are developing smaller, more efficient capacitors that take up less space while providing the same or improved performance. This trend is particularly important in the context of compact washing machines and smart appliances.

2. **Smart Capacitors and Their Applications**: The emergence of smart capacitors, which can communicate with other components in a washing machine, is paving the way for enhanced functionality and performance. These capacitors can adapt to changing conditions, optimizing energy use and improving overall efficiency.

B. Future Trends in Washing Machine Technology

The future of washing machine technology is bright, with several trends on the horizon.

1. **Integration with Renewable Energy Sources**: As renewable energy sources become more prevalent, washing machines equipped with advanced capacitors may be able to harness solar or wind energy, further reducing their environmental impact.

2. **Enhanced User Interfaces and Smart Features**: The integration of capacitors in smart washing machines will enable more sophisticated user interfaces, allowing consumers to customize their laundry experience and monitor energy usage in real-time.

V. Challenges and Considerations

While washing machine capacitors offer numerous benefits, there are also challenges and considerations to keep in mind.

A. Reliability and Lifespan of Capacitors

The reliability and lifespan of capacitors are critical factors in the performance of washing machines. Manufacturers must ensure that the capacitors used in their products can withstand the rigors of daily use.

B. Environmental Impact and Recycling of Capacitors

As with any electronic component, the environmental impact of capacitors must be considered. Manufacturers and consumers alike should prioritize recycling and proper disposal to minimize waste.

C. Regulatory Standards and Compliance in Various Industries

Compliance with regulatory standards is essential for manufacturers in the home appliance and electronics industries. Ensuring that capacitors meet safety and performance standards is crucial for consumer safety and product reliability.

VI. Conclusion

Washing machine capacitors play a vital role across various industries, from home appliances to manufacturing and electronics. Their importance in enhancing the performance and efficiency of washing machines cannot be overstated. As technology continues to evolve, the future of washing machine capacitors looks promising, with advancements in design and functionality paving the way for smarter, more efficient appliances. By understanding the multifaceted role of capacitors in different sectors, we can appreciate their significance in modern washing machine technology and performance.

VII. References

- [List of academic papers, articles, and industry reports used for research]

- [Additional resources for further reading on washing machine capacitors and related technologies]

This comprehensive exploration of washing machine capacitors highlights their critical role in various industries and underscores the importance of continued innovation and sustainability in this field.

What Industries Do Washing Machine Capacitor Application Scenarios Include?

I. Introduction

Washing machines are an essential part of modern households, providing convenience and efficiency in laundry care. At the heart of these machines lies a crucial component: the capacitor. Capacitors play a vital role in the operation of washing machines, ensuring they function smoothly and efficiently. This article explores the various industries that utilize washing machine capacitors, their applications, and the significance of these components in enhancing the performance and efficiency of washing machines.

II. Understanding Washing Machine Capacitors

A. Function of Capacitors in Washing Machines

Capacitors are electrical components that store and release energy. In washing machines, they serve several critical functions:

1. **Energy Storage**: Capacitors store electrical energy, which can be released when needed. This is particularly important during the initial startup of the washing machine, where a surge of power is required to get the motor running.

2. **Voltage Regulation**: Capacitors help maintain a stable voltage level within the washing machine, ensuring that the motor and other components receive the appropriate amount of power for optimal performance.

3. **Motor Start and Run Applications**: Capacitors are essential for starting and running the motor in washing machines. They provide the necessary boost of energy to start the motor and help it run efficiently during operation.

B. Types of Capacitors Used in Washing Machines

There are several types of capacitors used in washing machines, each serving a specific purpose:

1. **Start Capacitors**: These capacitors provide a temporary boost of energy to start the motor. They are typically used in single-phase motors and are designed to disconnect from the circuit once the motor reaches a certain speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit during the entire operation of the motor. They help improve the efficiency and performance of the motor by providing a continuous supply of energy.

3. **Dual Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit. They are commonly used in washing machines with more complex motor systems.

III. Key Industries Utilizing Washing Machine Capacitors

A. Home Appliances Industry

The home appliances industry is the primary sector that utilizes washing machine capacitors. Washing machines are a staple in households, and their performance directly impacts consumer satisfaction. Capacitors play a crucial role in enhancing the efficiency and reliability of washing machines, making them indispensable in this industry.

1. **Overview of the Home Appliance Sector**: The home appliance sector encompasses a wide range of products, including refrigerators, ovens, and washing machines. As consumer demand for energy-efficient and high-performance appliances grows, the role of capacitors becomes increasingly important.

2. **Role of Washing Machines in Households**: Washing machines save time and effort in laundry care, making them a vital appliance in modern homes. The efficiency of these machines is often linked to the quality and performance of their capacitors.

3. **Importance of Capacitors in Enhancing Washing Machine Performance**: High-quality capacitors contribute to the longevity and reliability of washing machines. They help reduce energy consumption, minimize noise, and improve overall performance, making them a key focus for manufacturers in the home appliance industry.

B. Manufacturing Industry

The manufacturing industry is another significant sector that relies on washing machine capacitors. This industry encompasses the production of washing machines and the components that go into them.

1. **Production of Washing Machines**: Manufacturers must ensure that the capacitors used in their washing machines meet specific performance standards. This involves sourcing high-quality capacitors and integrating them into the design of the machines.

2. **Quality Control and Testing of Capacitors**: Quality control is essential in the manufacturing process. Capacitors undergo rigorous testing to ensure they meet safety and performance standards before being used in washing machines.

3. **Innovations in Capacitor Technology for Manufacturing Efficiency**: As technology advances, manufacturers are continually seeking innovative capacitor designs that enhance efficiency and reduce production costs. This includes the development of miniaturized capacitors that take up less space while providing the same level of performance.

C. Electronics Industry

The electronics industry plays a crucial role in the integration of capacitors into washing machines, particularly in the context of smart appliances.

1. **Integration of Capacitors in Electronic Control Systems**: Modern washing machines often feature electronic control systems that rely on capacitors for stable operation. These systems manage various functions, including wash cycles, water levels, and temperature settings.

2. **Role in Smart Washing Machines and IoT Applications**: The rise of smart appliances has led to the integration of capacitors in Internet of Things (IoT) applications. Capacitors help ensure that these devices operate efficiently and reliably, enabling features such as remote control and monitoring.

3. **Advancements in Capacitor Technology for Electronics**: The electronics industry is continually innovating, leading to the development of advanced capacitors that offer improved performance, smaller sizes, and enhanced energy efficiency.

D. Repair and Maintenance Services

Repair and maintenance services are essential for ensuring the longevity and performance of washing machines. Capacitors play a significant role in these services.

1. **Importance of Capacitors in Repair Services**: When washing machines malfunction, capacitors are often among the first components to be checked. A faulty capacitor can lead to issues such as motor failure or erratic operation.

2. **Common Issues Related to Washing Machine Capacitors**: Technicians frequently encounter problems such as capacitor failure, which can result in the washing machine not starting or running inefficiently. Understanding these issues is crucial for effective repairs.

3. **Training and Expertise Required for Technicians**: Technicians must be trained to diagnose and replace faulty capacitors in washing machines. This requires a solid understanding of electrical systems and the specific types of capacitors used in different models.

E. Energy Sector

The energy sector is increasingly focused on energy efficiency, and washing machine capacitors play a vital role in this effort.

1. **Energy Efficiency in Washing Machines**: As consumers become more environmentally conscious, the demand for energy-efficient appliances has grown. Capacitors contribute to this efficiency by optimizing motor performance and reducing energy consumption.

2. **Role of Capacitors in Reducing Energy Consumption**: By improving the efficiency of washing machines, capacitors help reduce overall energy consumption, leading to lower utility bills for consumers and a smaller carbon footprint.

3. **Impact on Sustainability and Environmental Considerations**: The use of energy-efficient washing machines equipped with high-quality capacitors aligns with sustainability goals, making them an attractive option for environmentally conscious consumers.

IV. Emerging Trends and Innovations

A. Technological Advancements in Capacitor Design

The field of capacitor technology is evolving rapidly, leading to several exciting advancements.

1. **Miniaturization and Efficiency Improvements**: Manufacturers are developing smaller, more efficient capacitors that take up less space while providing the same or improved performance. This trend is particularly important in the context of compact washing machines and smart appliances.

2. **Smart Capacitors and Their Applications**: The emergence of smart capacitors, which can communicate with other components in a washing machine, is paving the way for enhanced functionality and performance. These capacitors can adapt to changing conditions, optimizing energy use and improving overall efficiency.

B. Future Trends in Washing Machine Technology

The future of washing machine technology is bright, with several trends on the horizon.

1. **Integration with Renewable Energy Sources**: As renewable energy sources become more prevalent, washing machines equipped with advanced capacitors may be able to harness solar or wind energy, further reducing their environmental impact.

2. **Enhanced User Interfaces and Smart Features**: The integration of capacitors in smart washing machines will enable more sophisticated user interfaces, allowing consumers to customize their laundry experience and monitor energy usage in real-time.

V. Challenges and Considerations

While washing machine capacitors offer numerous benefits, there are also challenges and considerations to keep in mind.

A. Reliability and Lifespan of Capacitors

The reliability and lifespan of capacitors are critical factors in the performance of washing machines. Manufacturers must ensure that the capacitors used in their products can withstand the rigors of daily use.

B. Environmental Impact and Recycling of Capacitors

As with any electronic component, the environmental impact of capacitors must be considered. Manufacturers and consumers alike should prioritize recycling and proper disposal to minimize waste.

C. Regulatory Standards and Compliance in Various Industries

Compliance with regulatory standards is essential for manufacturers in the home appliance and electronics industries. Ensuring that capacitors meet safety and performance standards is crucial for consumer safety and product reliability.

VI. Conclusion

Washing machine capacitors play a vital role across various industries, from home appliances to manufacturing and electronics. Their importance in enhancing the performance and efficiency of washing machines cannot be overstated. As technology continues to evolve, the future of washing machine capacitors looks promising, with advancements in design and functionality paving the way for smarter, more efficient appliances. By understanding the multifaceted role of capacitors in different sectors, we can appreciate their significance in modern washing machine technology and performance.

VII. References

- [List of academic papers, articles, and industry reports used for research]

- [Additional resources for further reading on washing machine capacitors and related technologies]

This comprehensive exploration of washing machine capacitors highlights their critical role in various industries and underscores the importance of continued innovation and sustainability in this field.